HZS25 concrete batching plant, belongs to a small mixing station, used for Chinese rural market, rural roads, small precast factory, for simple configuration.

A JS500 type concrete mixer,a PLD800 two warehouse batching machines, a cement silo, a screw conveyor pump, a cement gas metering system,the pneumatic control system and electric control system, can realize the production, little investment, quick returns.

Zhengzhou Jianxin's HZS25 concrete batching plant, cost about 20 thousand dollars, the specific price, should accord with the detailed configuration of the equipment, so that a set of HZS25 type concrete mixing station, the price will be different accord with different configuration.

Our company manufactures concrete mixer, concrete batching plant, concrete mixer truck, batching machine and cement silo. This blog is to display our products, share product information, discuss knowledge about concrete machine with friends who are interested in concrete field. Contact us: E-mail: manager@chinaconcretemixer.com http://concretemixermachine.cn/ http://chinaconcretemixer.net

Friday, February 24, 2017

Thursday, February 23, 2017

HZS 35 concrete batching plant for hot sale

Introduction of HZS35 concrete batching plant

Jianxin HZS35 concrete batching plant is a cycle type full automatic concrete batching plant,the host is a JS750 double horizontal shaft forced mixer,use PLD1200 batching machine,accurate measurement,high production efficiency.Powder using electronic scale metering,ingredients of high precision.The productivity is 35m3/h.Widely used in highway,bridge,power station,dam engineering field of construction engineering.

Compact Concrete Batching Plants have been designed in a more compact structure that it can be fitted on the 40''Containers. So they can be transported to all over the world easier and quick. This Compact Concrete Batching Plants make their users more flexible and free because of their advantages and their special designs.

Compact Concrete Batching Plants have been designed in a more compact structure that it can be fitted on the 40''Containers. So they can be transported to all over the world easier and quick. This Compact Concrete Batching Plants make their users more flexible and free because of their advantages and their special designs.

Compact Concrete Batching Plants, which reflect the experience of concrete batching plant history, provide the below advantages.

1.Its Compactness, Very Small Area is Needed to Install (Opportunity to Produce Concrete Even in Very Small Job Sites.)

2.High Production Performance

3.Less Transportation Cost

4.Easy and Economical Transportation to Overseas Countries

5.High Quality and Precise Concrete Production (with Fully Automated Industry Computerized Control System)

6.Quick Installation and Start Up Period (1-2 days)

7.Easy Maintenance and Low Operating Cost

E-mail: manager@chinaconcretemixer.com

Tel: +86-371-86599393

Fax:+86-371-64674111

Address: East of Xingyang South Bus ,G310(national highway),Henan 450100,China

HZS 25 concrete batching plant for hot sale

Introduction of HZS25 concrete batching plant

Jianxin HZS25 Concrete Batching Plant has excellent environmental protection, dust collection system and anti-noise designed.

It adopts JS double shafts concrete mixer which is abe to produce plastic and dry hard concrete, etc.

This concrete batching plant is widely applied for large and medium sized construction projects, road and bridge projects, and precast factory of concrete product.

Advantage

Possess the function of automatic compensation.

Adopt combined structure and modular units.Adopt electronic scale to measure powder and water material with high batching accuracy.

1. This kind of continuous concrete mixing plant has excellent environmental protection, dust collection system and anti-noise designed.

2. Jianxin HZS25 concrete batching plant is fully automactically controlled by computer system with friendly man-machine interface.

3. Jianxin JS500 mixer, excellent mixing performance with high efficiency and high productivity

4. Stationary modular structure, fast and easy to install.

5. Reliability: 30 years of experiences in manufacturing concrete mixing plants.

6. Stability and durability: adapt and apply the most advanced technologies around the world.

|

| concrete batching plant |

E-mail: manager@chinaconcretemixer.com

Mobile (WhatsApp): (+86) 18437125333

Tel: +86-371-86599393

Fax:+86-371-64674111

Address: East of Xingyang South Bus ,G310(national highway),Henan 450100,China

The notes in installing concrete batching plant

The problem of installation of concrete batching plant/mixing station exists for a long time, I hope this paper can help customers.

1, Because of the concrete mixing station manufacturing factory with the use of venues generally require long-distance transport, so before installation,it need to check again, to see if the mixer equipment screw loosening, weld rupture, and vent fouling problems.

2, the installation should be carried out step by step, the first mixer host installation, and then the operating console, and then followed by the ingredients, conveyor belt, etc., cement silo can be installed in the final. Step by step to the benefits that the main part of the machine and the minor part can fit tightly and do not cause errors.

3, At the end, installed cable part, this part should be careful, Because of the wrong wiring will cause an accident, but also to ensure the installation of machine components to keep dry, and each groove tube do protection work.

4, after the installation is complete, do not rush to test the machine, and then carefully check again, the test machine to be hours, should be adjusted after each component, and then the whole mixing station test machine.

What should we pay attention to in disassembling the batching plant

1 Banning sledge clearance accumulated in the concrete mixer drum of concrete, only can clear it with a chisel;

2 After the shutdown the concrete batching plant/mixing station, and pour water and gravel into the mixing drum for 10 to 15 minutes to clean, and then sort water and pebble out. When cleaning, turn off the power;

3 cleaning should be carried out regularly, regular maintenance procedures for the maintenance and maintenance of the project, such as cleaning, lubrication, oil and so on

Wednesday, February 22, 2017

Do you dare to buy it which the price is lower than the peer mixing station ?

Customers pay attention to equipment prices, equipment prices must comply with the laws of the market, if the price of the mixing station is very low, you must be vigilant, it may be refurbished machines, refurbished machines exist security risks in use, you should check carefully in the purchase of mixer / mixing station/concrete plant, please do not hoodwinked.

1 check the overall appearance of the mixer

The formal new concrete mixer / concrete mixing station main structure without obvious deformation, welding, crack. The installation is in accordance with the requirements, the parts and accessories are complete, the machine is clean, no rust, no obvious traces of concrete. The refurbished machine in the details of defects, consumers should carefully check.

2 check the safety device

Regular new concrete mixer / mixer hopper action sensitive and reliable. The clutch transmission power is effective, the separation is thorough, the brake is reliable, the hopper motor is reliable, does not have the slide phenomenon. Concrete mixer wire type, quality and specifications in accordance with the regulations, the wear and fracture of wire rope card does not exceed the prescribed, in accordance with the specification, open gear and belt wheel shield complete safety latch hook and security hopper on the track of sound, completely. Refurbished machines is far less than this effect.

3 check the drive

The original new mixer / mixer station is running smoothly, the connection is reliable, the gear mesh well,Drive belt consistence, force uniform, no fault.The chain, sprocket tooth bite phenomenon.Reducer functioning as ring, good seal.The motor work as ring, temperature rise within the rules.Good insulation and grounding requirements.

Jianxin Machinery alert users to buy concrete mixer must go to formal manufacturer, not greedy..

What should we pay attention to when we buy a concrete mixer?

What should we pay attention to when we buy a concrete mixer?

|

| concrete plant |

With the continuous development of society, the construction industry outlook is very good, the concrete mixer needs more and more, but the concrete mixer types on the market is a lot, which brought a lot of trouble for customers, although the choice have more kinds, but so many choices inevitably worry a problem in quality to buy the concrete mixer. Then we choose the following aspects of concrete mixer to discuss:

1, production scale: according to their annual production scale, as well as their own production capacity and sales situation, decided to buy what kind of concrete mixer equipment.

2, production quality: when you need to produce high quality products, you need to buy the reliable concrete mixer, just in this way you can produce high quality concrete.

3, production capacity: according to the actual construction site size and environment, choose the appropriate concrete mixer.

4, equipment characteristics: we need to consider the advanced nature and reliability of concrete mixer, considering its comprehensive application ability.

5, price: at the same time, we also need to consider the price, which is a measure of cost savings.

6, technical performance: we can not consider the pursuit of technical costs alone, but also can not only reduce costs in order to save costs, we need to compromise, to find a suitable point for themselves.

Combined with the above points, I believe we can basically determine their basic requirements for concrete mixing equipment, and then with the manufacturer's business or technical personnel to communicate, you can choose to buy the concrete mixer which suit you.

Ask:

Answer:

JS1000 is forced horizontal shaft mixer, according to its different stirring mode (single motor or double motor) differences in feeding way, the price is about 15 thousands dollars.

Ask:

Is there a mobile HZS180 type concrete mixing station?

Answer:

There is’nt a mobile HZS180 type concrete mixing station in China, only the fixed type HZS180 concrete mixing station(HZS180 concrete batching plant). If there is a manufacturer can produce mobile HZS180 station, customers should be careful, be careful deceived.

Ask:

How many concrete trucks are needed in the production line of a HZS180 type concrete mixing station?

Answer:

Concrete transport vehicle subjected to many conditions, such as the distance from the construction site, the size of tank itself, the general construction of a concrete mixing plant HZS180 production lines, 10 to 15 of the concrete transport vehicle basic enough.

Ask:

HZS75 concrete mixing station need how much transformer?

Answer:

Construction of a HZS75 concrete mixing plant production line, it is recommended that users of the total power of the transformer is not less than 150KW.

Ask:

HZS50 type concrete mixing station control system is a computer?

Answer:

There are two kinds of electric control system of HZS50 type concrete mixing station, one is simple centralized control system, the other is full automatic computer control system.

Ask:

How much power is needed to build a concrete mixing plant? I have to plan the transformer

Answer:

The electric power in mixing station is directly related to station type and configuration, one of the most important principles of the selection of the transformer, the sum must be slightly larger than all the electric power, to ensure that the transformer can not be overloaded.

Ask:

What are the most popular brands of JS2000 concrete mixers?

Answer:

Ask:

Which mode is the HZS90 station’s batching machine?

Answer:

At present, in accordance with industry standards, sand batching machine supporting the use of the basic 90 stations, are used in batching machine PLD2400 four positions measured separately, there are customers to choose the batching machine larger versions of the gravel mixture.

Tuesday, February 21, 2017

Zhengzhou Jianxin Machinery Co., Ltd: How much does it cost to buy JS500 concrete mixer

Zhengzhou Jianxin Machinery Co., Ltd: How much does it cost to buy JS500 concrete mixer: JS500 CONCRETE MIXER is very popular all over the world, it has a small investment, big returns, high efficiency, low energy consumpti...

How much does it cost to buy JS500 concrete mixer

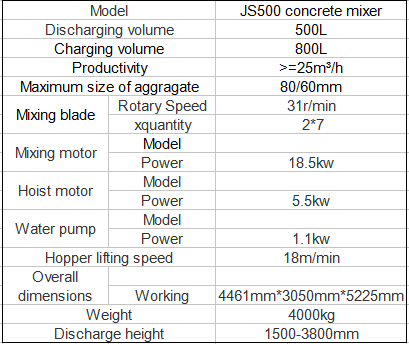

JS500 CONCRETE MIXER is very popular all over the world, it has a small investment, big returns, high efficiency, low energy consumption and equipment advantages, so it has been a lot of JS500 consulting, forced mixer price and equipment parameters, I will give you a detailed analysis in this article.

No matter what kind of product, the price is always the focus of attention, but the price is determined by the value of the product, which is also a common principle in any product, JS500 forced mixer is no exception.

JS500 forced mixer is composed of a mixing drum, a feeding device, a water supply device, discharge device and a series of parts and accessories of different manufacturers selection of quality brand can not be exactly the same, so for the same type of JS500 forced mixer, the market price is also different. The user can select some strength and experience large manufacturers to buy JS500 concrete mixer equipment, because of the large manufacturers will provide a cost-effective configuration according to your project, and then list the detailed price list, but also to the factory to visit, to inspect the JS500 forced mixer every zero parts quality, to buy the rest assured, comfortable use!

Friday, February 17, 2017

Concrete Mixer JS500,500 is the discharge capacity, is one time match with so much volume? How to determine the proportion of concrete in accordance with 500

Concrete Mixer JS500,500 is the discharge capacity, is one time match with so much volume? How to determine the proportion of concrete in accordance with 500

The 500 refers to the maximum capacity of a plate material for 500L. concrete is usually in accordance with the whole bag of cement (for cement added) to calculate other material consumption, and the total control of a plate material does not exceed 500L (the total dosage of /2400/1000 by batch estimate) can be reduced to (if more than 1 less cement and other materials. The corresponding). If it is bulk cement, according to each of the 1 disc clinker 500L calculation of the amount of each material ingredients.

China Js500 Twin Shaft Mini Electric Compulsory Concrete Mixer With Loading Hopper In Cement Production Line

JS500 type concrete mixer is double horizontal shaft forced mixer, this machine has reasonable design structure, strong mixing effect, good mixing quality, high efficiency, low energy consumption, novel layout, high degree of automation, convenient operation and maintenance.

The machine can stir the dry concrete, plastic concrete, fluidity concrete, light-weight aggregate concrete and various kinds of mortar, is a kind of high efficiency models, is widely used.

The machine has the advantages of stand-alone operation and PLD series batching machine composed of simple concrete mixing station, but also for the mixing station to provide a host. JS500 concrete mixer is suitable for various kinds of large, medium and small prefabricated factory and roads, bridges, docks and other industrial and civil engineering.

FOB Price:

| |

Min.Order Quantity:

|

1 Set/Sets

|

Supply Ability:

|

100 Set/Sets per Month

|

Port:

|

Qingdao, Tianjin, Shanghai

|

Payment Terms:

|

L/C,T/T,Western Union,MoneyGram,Paypal, Credit card, Cash

|

Quick Details

Condition:New

Place of Origin:Henan, China (Mainland)

Brand Name:Jianxin

Model Number:JS500

Motor Power:15 Kw

Mixing Power:18.5 Kw

Charging Capacity:800L

Reclaiming capacity:500L

Speed of Mixing Drum:31 r/min

Water Supply Mode:Water Pump

Working Cycle Period:60s

Discharge Way:Automatic

Outline Dimension:4461*3050*4180mm

After-sales Service Provided:Engineers available to service machinery overseas

Product name:JS500 concrete mixer machine

Output:25 cbm/h

Lifting power:5.5kw

Mixing speed:31 r/min

Mixing blade quantity:2*7

concrete mixer type:forcing type twin horizontal shafts

Max. aggregate size:50mm

Color:red or as request

Water pump power:1.1kw

Application:all industrial and civil construction projects

Packaging & Delivery

Packaging Details:

|

1, For full container load, main body with plastic film surrounded or in nude, key parts and spare parts in strong export wooden or iron case. 2, For less than container load, main body and all spare parts in strong export wooden or iron case.

|

Delivery Detail:

|

Shipped in 7 days after payment

|

Product Description

Introduction of JS500 concrete mixer

Combined with domestic and overseas advanced techonology, JS series concrete mixer could work individually or to be simple concrete mixing plant with PLD series batching plant, also could provide matching host for mixing plant. So it is a widely used high efficiency model. JS500 concrete mixer is reasonably and newly designed, convenient for use and maintanance. Also can be customized according to customers’ personalized request.JS500 concrete mixer has wide applications, such as all kinds of factory for prefabrication, roads, bridges, irrigation works, wharf and other industrial or civil construction projects. Could mix hard concrete, plastic concrete, fluidity concrete, light orthopaedic concrete and all kinds of mortar.

What's the working principle of JS500 concrete mixer?

•The break motor drives rotation of the coiling block, when the hopper climbs up to a certain height by loading track, the hopper door will open automaticlly, and raw materials will be put into the stirring pot.

•There are limit switches on loading shelf to assure the accurate position of the hopper. Js series concrete mixer has 2 limit switches on upper limit positon, seperately offers positioning and protection for the hopper. Also there is 1 limit switch on lower limit position.

•The loading shelf of JS500 concrete mixer machine can be folded for transportation convenience.

•There are limit switches on loading shelf to assure the accurate position of the hopper. Js series concrete mixer has 2 limit switches on upper limit positon, seperately offers positioning and protection for the hopper. Also there is 1 limit switch on lower limit position.

•The loading shelf of JS500 concrete mixer machine can be folded for transportation convenience.

Details of JS500 Concrete Mixer

What are features of JS500 concrete mixer?

•Adopts forcing type twin horizontal shafts, with high mixing quality and working efficiency for concrete of various ratios.

•The forced water supply system sprays equably and has washing function for the mixing system.

•Adopts the electronic weighing syetem to measure all the aggregate cement water liquid additive.

•The electrical system adopts imported famous brand parts and has credible performance.

•Powdery materials are processed in hermetic condition in all procedures including loading, burdening, measuring, charging, mixing and discharging. There is a high quality dust remover in the main mixing pot, also the mixing pot and belt conveyor are sealed. Vastly reduced dust and noise pollution.

•Js500 concrete mixer machine has double mixing blades quantity compared with common twin shaft horizontal mixers. Outter ring pushes material to be boiling status, while inner ring shovel shears in radial direction, realize violent and sufficient mixing for material in a short time.

•Electrical opening style or pneumatic discharging, avoid the shortcoming of raw material remaining.

•Optimal designed hopper, easy to clean, better charging ability.

•Reasonably designed with elegant appearance, quick assembling and disassembling, convenient transportation.

Parameters ofJS500 concrete mixer:

JS series concrete mixer varies from JS500 to JS3000.

Model

|

Discharging capacity

|

Charging capacity

|

Theoretical output

|

Max grain diameter

(gravel/grait)

|

Mixing blade rotating speed

|

Mixing power

|

Lifting power

|

Water pump power

|

Dimention

| |

JS500

|

500L

|

800L

|

≤25m³/h

|

≤40/50

|

31(r/min)

|

2*7

|

18.5 kw

|

5.5 kw

|

1.1 kw

|

4461*3050*4180 mm

|

JS750

|

750L

|

1200L

|

≤35m³/h

|

≤40/50

|

31(r/min)

|

2*7

|

30 kw

|

7.5 kw

|

1.1 kw

|

4461*3050*4180 mm

|

JS1000

|

1000L

|

1600L

|

≤60m³/h

|

≤60/80

|

19.5(r/min)

|

2*8

|

37 kw

|

15 kw

|

2.2 kw

|

4320*2200*3300 mm

|

JS1500

|

1500L

|

2400L

|

≤90m³/h

|

≤60/80

|

19.5(r/min)

|

2*8

|

44 kw

|

18.5 kw

|

2.2 kw

|

4720*2200*3000

mm

|

Model

|

Discharging capacity

|

Charging capacity

|

Theoretical output

|

Max grain diameter

(gravel/grait)

|

Mixing blade rotating speed

|

Working circulation

|

Dimention

| |

JS2000

|

2000L

|

3200L

|

≤120m³/h

|

≤80/100

|

21(r/min)

|

37*2

|

60 s

|

3500*2400*2125 mm

|

JS3000

|

3000L

|

4800L

|

≤150m³/h

|

≤100/120

|

21(r/min)

|

55*2

|

60 s

|

4050*2680*2150 mm

|

Packaging / Delivery

Company Introduction

About Jianxin Company

1,Founded in 1986 and located in central China, jianxin machinery manufacturing company ltd. combines scientific research, manufacture, sales and service together. Dedicated in construction machinery for 30 years, Jianxin now has 2 factories which cover an area of 220 thousand square meters, including 60 thousand square meters building area. Jianxin now has more than 500 staffs,including 26 senior mechanical engineers, 12 electrical engineers, 36 technical engineers, 128 senior electric welders, 6 ISO9001 internal auditors and more than 300 common staffs. While there are more than 80 sets of various lathes and precision machining equipments.

2,Jianxin brand product contains 8 series and totally 46 kinds, mainly are HZS25-HZS240 concrete mixing plant, WBZ300-WBZ800 stabilized soil mixing plant, YHZS25-YHZS100 mobile mixing plant, CPM500-CPM2000 vertical planetary concrete mixer, JS500-JS4000 horizontal shaft concrete mixer, PLD800-PLD4800 concrete batching machine, 50T-500T cement silo, HYC3m3-HYC10m3 concrete mixer truck, etc. All products are accord with China national standard and have ISO international certificate of quality system, European CE certificate and export inspection exemption together with many national patents.

2,Jianxin brand product contains 8 series and totally 46 kinds, mainly are HZS25-HZS240 concrete mixing plant, WBZ300-WBZ800 stabilized soil mixing plant, YHZS25-YHZS100 mobile mixing plant, CPM500-CPM2000 vertical planetary concrete mixer, JS500-JS4000 horizontal shaft concrete mixer, PLD800-PLD4800 concrete batching machine, 50T-500T cement silo, HYC3m3-HYC10m3 concrete mixer truck, etc. All products are accord with China national standard and have ISO international certificate of quality system, European CE certificate and export inspection exemption together with many national patents.

3,Foreign customers from more than 30 countries, including africa, middle east, south and north america, europe and asia. Jianxin brand products and service are widely praised!

Customer Visit

1,Jianxin dedicated in concrete mixing industry for 30 years since 1986.China top10 concrete plant factory, with core advantage in design, quality and raw material sourcing.

2,Professional pre-sales service, professional technical consultant to answer all your questions and give valuable suggestions.

3,Prompt and fluent communication, save your time. After getting your enquiry, in 1 working day we will offer detailed program design and quotation, all details will be listed clearly.

4,Quick delivery and good quality control. For single machine, delivery time within 5 days. For production line, delivery time within 15 days.

5,Top experienced engineers assure nice user experience, exquisite apperance design and easy to handle.

6,Experienced in foreign trade, clearly knows every procedure in foreign trade, save your time and energy.

2,Professional pre-sales service, professional technical consultant to answer all your questions and give valuable suggestions.

3,Prompt and fluent communication, save your time. After getting your enquiry, in 1 working day we will offer detailed program design and quotation, all details will be listed clearly.

4,Quick delivery and good quality control. For single machine, delivery time within 5 days. For production line, delivery time within 15 days.

5,Top experienced engineers assure nice user experience, exquisite apperance design and easy to handle.

6,Experienced in foreign trade, clearly knows every procedure in foreign trade, save your time and energy.

Customer Case

Website: http://chinaconcretemixer.net

E-mail: manager@chinaconcretemixer.com

Mobile (WhatsApp): (+86) 18437125333

Tel: +86-371-86599393

Fax:+86-371-64674111

Address: East of Xingyang South Bus ,G310(national highway),Henan 450100,China

As a professional concrete mixer and concrete batching plant manufactures in China with over thirty years of experience, we mainly supply you the following products:

Concrete mixer;Concrete mixing plant;Mobile concrete mixing plant;Stabilized soil mixing station:;Concrete transport mixer:;Sheet cement silo:;Bale breaker:;Containerized(module) concrete mixing plant:;Screw conveyor;Control system;

Please visit our website for more information

Subscribe to:

Posts (Atom)