FOB Price: US $28,500 - 66,000 / Unit

Min.Order Quantity: 1 Set/Sets

Supply Ability: 85 Unit/Units per Month

Port: QINGDAO,SHAGNHAI

Payment Terms: L/C,T/T

Quick Details

Place of Origin: Henan, China (Mainland)

Brand Name: JIANXIN BRAND

Model Number: WBZ600

After-sales Service Provided: Engineers available to service machinery overseas

Company Pattern: Factory&Manufacturer

Company Establishment: in 1986

Number of Employees: 350

Color of Machine: Blue,white or Yellow

Certificates: ISO2001,IAF

Service Time: 24 hours

Agent Location: Middle east,south east and Africa

Flexible payment terms: 100%L/C,Usance L/C Payable at sight

EPC Consultant: Offering feasbile report and planing

Lower rate of earnest money: 20%T/T suitable for huge amounts contract

Packaging & Delivery

Packaging Details: Dis-assembly and naked into 20GP,40GP or 40HQ.

Depended on size of plants

Delivery Detail: 15-25DAYS

Specifications

1 Higher efficiency

2 Beautiful appearance

3 Plenty of storage

Construction:

Application Background

WBZ600 stabilized soil mixing station (mixing station) belongs to the type of combination of the dis-assembly machine and the agitation type is twin-shaft compulsory continuous,which can be stabilized soil mixing gravel, lime stabilized soil, adapted to the highway, Ⅰ grade highways, Ⅱ grade highways, urban roads, airports, stadiums and other basic construction materials as well as used quicklime , slaked lime (10-15% moisture content), soil, sand, fly ash, cement and other raw materials, production of lime and other basic materials.

Feature&Advantage

1.WBZ600 stabilized soil mixing station (mixing station) host using a continuous twin shaft mixer without lining, easy maintenance, spices uniform, high production efficiency.

2.Ingredients uses electronic weighing or volume measurement, accurate and reliable, the ratio changes rapidly.

3.Computer control system manages the entire process, manual and automatic selection, easy operation, good reliability.

4.Velocity modulation adopts international advanced frequency control mode or electromagnetic speed control, will be able to lower energy consumption, stepless, fully ensure the reliability of equipment operation.

5.Water system uses turbine flow-meter with intelligent, accurate calculation, intuitive displaying.

6.Aggregate, finished feed conveyor adopts seamlessvulcanized joint tape or large angle annular rib belt waveform, compact, stable, reliable, easy deviation, effectively improve the life of the belt.

7. Aggregate warehouse adopts modular building block combination, flexible, suitable for different levels of demand.

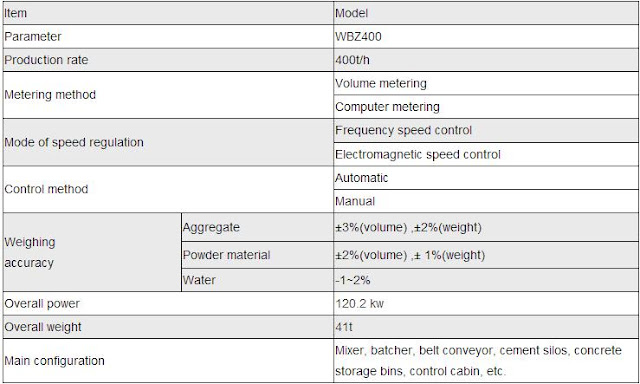

Item

|

Model

| |

Parameter

|

WBZ600

| |

Production rate

|

600t/h

| |

Metering method

|

Volume metering

| |

Computer metering

| ||

Mode of speed regulation

|

Frequency speed control

| |

Electromagnetic speed control

| ||

Control method

|

Automatic

| |

Manual

| ||

Weighing

accuracy

|

Aggregate

|

±3%(volume) ,±2%(weight)

|

Powder material

|

±2%(volume) ,±1%(weight)

| |

Water

|

-1~2%

| |

Overall power

|

170.5kw

| |

Overall weight

|

54t

| |

Main configuration

|

Mixer, batcher, belt conveyor, cement silos, concrete storage bins, control cabin, etc.

| |

E-mail: